Industry 4.0

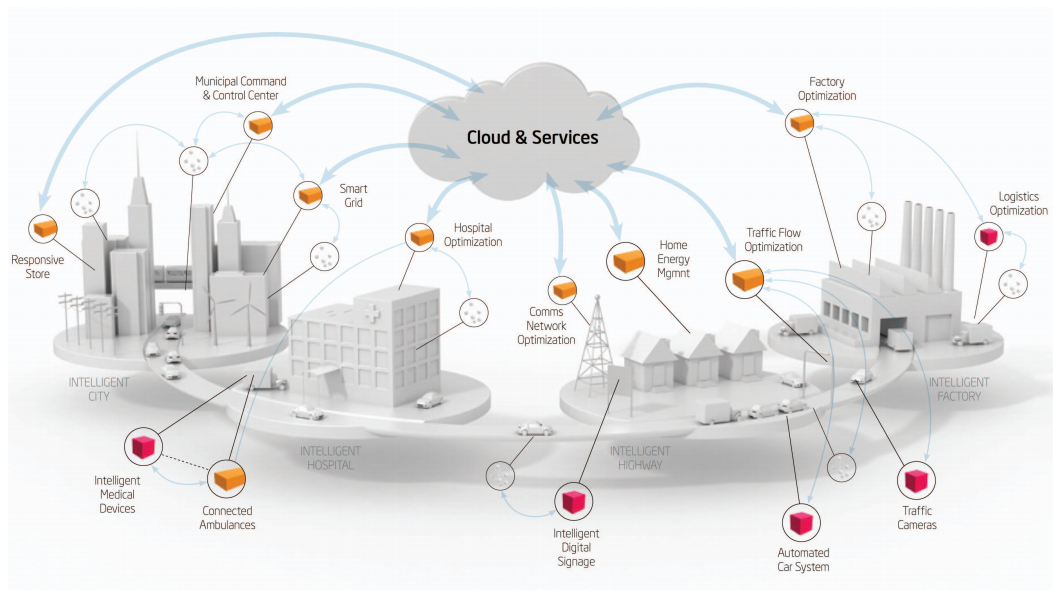

The promise of Industrial IoT and Industry 4.0 is dependent on consuming large amounts of data from the industry assets like machines, learn from them in real time and make decisions based on that learning. Training systems with ability to learn by just looking at the data from your factory/business has allowed ChirpIQ to bring you a system that gears you up for the next industrial revolution

Industry 4.0 needs flexible systems to quickly provision new services and learning mechanisms. ChirpIQ has patented technology to create learning models from almost any data stream. It learns from your data and more it is used, better decisions it can make. It is also based on micro services architecture, allowing it to add and remove services with ease, without affecting the other services on the system.

Use cases like predicting machine failures, determining time to failure, predicting service needs in a smart city, alerting on possibility of a certain transformer getting overloaded, forecasting need for hospital services and predicting probability of a claim being paid for a certain procedure code are just some of the business opportunities that industries will be able to execute using ChirpIQ system.

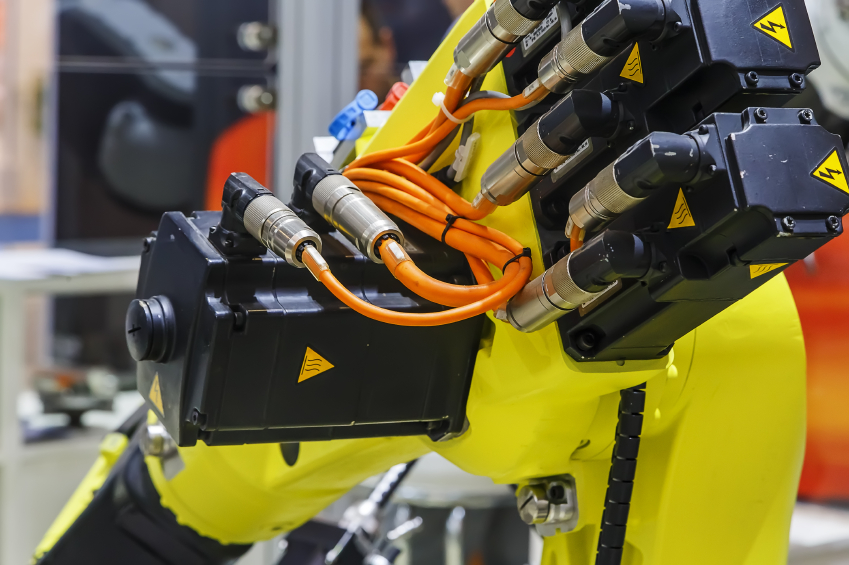

Injecting intelligence into “dumb” machines starts with gathering data from installed sensors. ChirpIQ SMART Platform then steps in to take high speed data from all these sensors and learns the machine behavior in realtime. This continuous learning creates the intelligent systems – the final promise of IoT. We, at ChirpIQ, are dedicated to bring you nextgen computing.

Contact US For More Information

Industrial IoT

Intelligent Prediction

We do not have a crystal ball but our system comes close. We can predict issues with your machines by just “listening” to them. We continuously “listen” based on sensor data gathered from the machines. Knowing the normal operational states of the machines let us detect anomalous behavior. This behavior is used to determine new operational states or faults. Our proprietary learning algorithms are used to determine faults and time to failure of machines

Features

– Real time machine condition monitoring and analysis

– Alerts on equipment degradation to improve operations

– More precise and continuous evaluation of assets

– Ability to integrate with existing systems, with plugins

– Evaluate machine against similar machines

– Predict failures and provide maintenence recommendations

Benefits

– Reduced costs due to unnecessary maintenance and/or replacement of assets

– Reduced unexpected failure of machinery

– Cost reduction due failure prevention

– Maintenance plans tied to condition of the equipment

– Cost saving associated with manual monitoring and diagnostics of machinery

Our Process

Provisioning

-

01

ChirpAnywhere System can be installed in the public cloud or a private cloud within hours and scaled up or down as needed

-

02

Industrial sensors are installed on the machines to gather data and learn the behavior of the machines

-

03

An ecosystem is created to represent the factory and machines in it. This is done using a visual tool provided with the system.

-

04

Analysis reports, UI widgets and machine learning are configured for the client, using a visual web based interface.

Initial Operations

-

01

As data from sensors streams to the System, The System starts to build individual machine profiles and the inter-machine dependency profiles.

-

02

System initiates learning model creation to learn the normal operation of each machine and machine group.

-

03

The model is saved and updated as more data is processed. The normal operating modes are recognized and labeled

-

04

The models are used as filters in real time data streams from the sensors and the learning is used to make operational and other decisions

Ongoing Operations

-

01

The System’s decisioning component uses the learning models to provide real time decisions on current stream of data from the sensors

-

02

The System generates defined analytics reports from the real time stream of data and displays it on the UI

-

03

Based on the data from the machines, the system can determine if there is any anomaly in any one or more machines.

-

04

The system continues to evolve as it processes more data, essentially getting smarter as it is used.